DripStop

It’s about keeping your contents dry

after you have a roof over it

Dripstop…

- Saves Money – No labor cost for installing insulation

- Saves Time – Half the time on the roof

- Can be Installed in windy conditions

- Makes identifying leaks much easier

- Safer – Injuries are less likely during installation

- Shipped ready to install with not extra application

DRIPSTOP has become the world’s best-selling condensation control product by being faster, cheaper and more durable.

Fight condensation without insulation. Vapor barriers can tear or be cut, causing insulation systems to fail. Don’t go to the time and expense of laying down insulation and vapor barrier when you are just trying to stop condensation. DRIPSTOP traps that moisture like a sponge and holds it until conditions rise above the dew point and it burns back into normal humidity.

DRIPSTOP costs up to 25% less than traditional solutions because installation of insulation can be skipped. Cutting out this step of the building process can also cut up to half the time for workers on the roof.

DRIPSTOP reduces the risk of falling while walking on top of insulation on the roof frame or wrestling with cumbersome rolls of insulation and reaching out over the panel with a slap-tacker. This means less risk to you and your workers.

It can allow you to work on the roof when wind and weather conditions would otherwise keep workers off of it.

Condensation Control Solution

ADVANTAGE OF USING DRIPSTOP WITH THE EAGLE PRO PANEL

- Saves Money – No need to insulate against condensation. No more costs for installing insulation.

DripStop is applied at the time the panel is formed. - Saves Time – Completely cuts out one step of the building process, and up to half the time on the roof.

Arrives on the jobsite pre-installed on the panels. - Vapor Barrier – Eliminates the need to provide and install conventional vapor barrier.

- Easy to Clean – Spray with a hose or pressure washer.

- Durable – Adhered to the panel for lasting performance. Will not deteriorate, tear or rip. Very difficult to slice through.

- Helps Prevent Corrosion – Test have proven it adds another layer of protection specifically from the corrosive elements in livestock confinement.

- Reduces Noise – Improves acoustical insulation.

- Selection – Available in Eagle Pro.

- Warranty – 20 year adhesion warranty.

How it Works

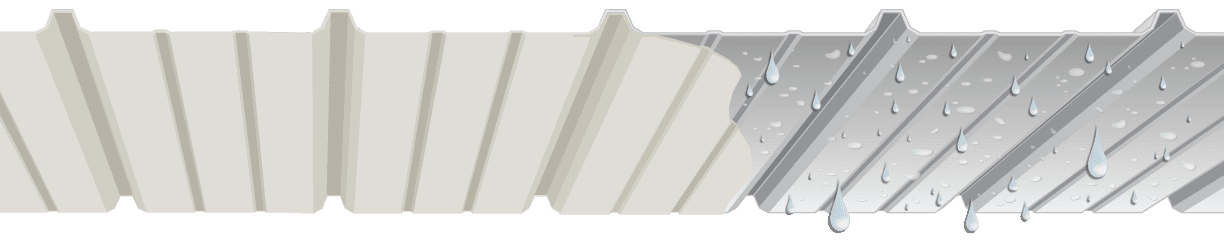

As the temperature and humidity conditions reach the dew point, moisture condenses on the underside of metal roofing forming droplets of water.

When Dripstop, an internationally patented CCM (Condensation Control Membrane), is pre-applied to Eagle Pro in our manufacturing facility in Tomah, Wisconsin it provides a medium for trapping this moisture in the specially designed pockets formed in the membrane. The material holds that moisture until conditions go back below the dew point and is then released back into the air in the form of normal humidity.

Areas of Use

- Post Frame/Agricultural Buildings

- Steel Buildings

- Self-Storage

- Workshops/Unattached garages

- Open Walled Structures

- Carports, Truck Ports & RV Storage

Post Frame

The post frame market is DRIPSTOP’s larges market Segment. This market includes agricultural buildings, equipment storage, grain storage, or office. These are customers that just do not want it to rain inside. – Segment does not need to be capitalized. Office probably needs to be changed to shop, and larges should be largest.

Livestock Confinement

On structures built for livestock, the layer of rubber between the membrane and the steel panel can help reduce corrosion, and may prolong the life of a building. It is advantageous to use DRIPSTOP for these applications because it is easy to clean, anti microbial and hoses off or can be pressure washed.

In animal confinement, condensation is highly acidic. Acid dripping down on animals can hurt yield. Dairies and horse barns in particular seem to show higher interest.

Self Storage

The durability of DRIPSTOP is astounding. Unlike traditional vapor barriers, no matter what you do to it, you can not screw it up! This is the largest benefit for self storage facilities, People will shove anything into a self storage unit, even if it is filled up to the ceiling. Look at any older facility and you will usually find vapor barrier patchwork repairing customer damage. Patches often are not put on until after a unit becomes empty again, and by that time the insulation is often ruined. Adding to further expense.

Open Walled Structures

Carports, truck ports, lumber yards, garden centers, covered storage, stack houses are all candidates for DRIPSTOP installations.

Other Areas of Use

Aircraft/Boat hangars, cold storage, unattached garages, workshops, sheds, DIY builds, sports stadiums, retrofit roofing.

CONTRACTOR & INSTALLER TRAINING

Post Frame

We recommend heat treating the edges, eaves and end laps for a couple of reasons. By itself, DR!PSTOP is resistant to mold and mildew. But as dirty rain water runs down a roof, organic material can get trapped in the air pockets in the membrane. These organics provide food for mold and mildew to feed off of and grow from. Besides hurting the appearance, this mold and mildew can spread once it takes hold. This can accelerate the second problem which is wicking moisture in the building. Glazing prevents the wicking of moisture back up which can slow the evaporation process. On end laps (panels lapped over each other from ridge to eave typically found in wider buildings where a single panel length is not possible), heat treating keeps the water from wicking in as it runs down the roof during rain or snow. Holding water on a panel like this can void manufacturers’ warranties.

How to Glaze the Edges / Eaves

Since the material is polyester, it melts when heated by either a heat gun or open flame. The key is to melt the material completely until it looks like dots. We recommend using the heat gun for safety purposes.

It should be moved over the target area. When using the heat gun, place it approximately 1” – 2” inches from the material and move the gun CONSTANTLY over the material until it melts. The material will have a brail or raised dot like appearance as it melts.

The goal is treat all of the material that the exposed edge/eave can’t wick the run-off moisture; approximately 2 inches. And it will feel coarse to the touch. While some Builders have used other methods successfully, we recommend the heat gun. End laps are typically done before the panels are on the roof, either on the lift or on saw horses sat out for this purpose.